Centrifugal fans consist of an impeller in a casing having a spirally shaped contour. The double-discharge volute casing is a structural constraint and is maintained for its shape.

New Design Radial Fan Centrifugal Fan Industrial Fan Fan

In addition to that sealing devices are used in between the shaft and the casing.

. Centrifugal Blowers Products Use. Performance reliability and cost-effectiveness are the main criteria in the design. The redesign effort was geared towards meeting the design volute exit pressure while reducing the power required to operate the fan.

Classical fan and blower basic spiral casing design is based on a free vortex flow pattern and the assumption of a circumferentially uniform flow at the operating point where the flow rate through the impeller is equal to the flow rate through the spiral casing eg. When the fan rotates creates low pressure zone at the inlet thus intakes. The belt drive design has been made as compact as possible.

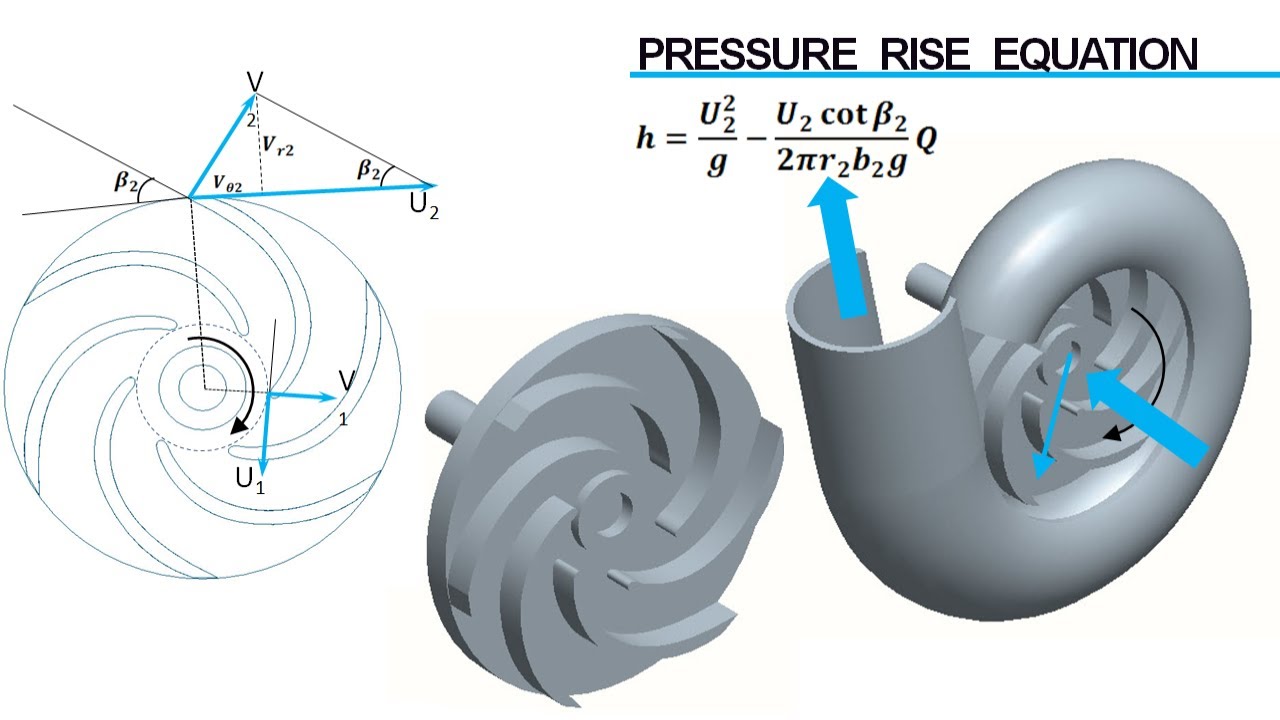

The air enters the impeller in an axial direction and is discharged at the impeller outer periphery. The design of centrifugal blowers includes a motor fan wheel and a housing. Generally as shown in FIG.

Lack of adequate number of blowers as well as tge use of unsuitable type of blower also lead to the total collapse of the gasification processThis research. Sometimes centrifugal fans are called radial flow type fans. Is given as frozen rotor impeller and casing interface is given as frozen rotor z Nodes Elements 8 38133 170312 12 38293 170360 16.

Published 14 August 2019. In these the casings of the blade are made up of sheet metal of varied thicknesses. Martins Engineering College Dhullapally Hyderabad Abstract Blowers are one of the types of turbo machinery which are used to move air continuously with in slight increase in static pressure.

Thandar Phyoe Min Than 1 author C. Of air at 60 F and design speed 3450 rpm. The most important is the centrifugal fan impeller which straight or curved metal blades can construct to the two sides of the rotor with the help of the welding process.

The double-discharge volute casing is a structural constraint and is maintained for its shape. Inlet guide vane IGV The inlet guide vane controls the operation by varying the stream into the blower. Centrifugal blower casing design Written By yennard Friday March 18 2022 Add Comment Edit.

And a separate blower system with 5 HP motor fitted at one end of the plant. Design Of 5 Kw Radial Type Centrifugal Blower casing inproceedingsThandar2019DesignO5 titleDesign Of 5 Kw Radial Type Centrifugal Blower casing authorAye Mya Thandar and Phyoe Min Than and Nang Sein Mya and Cho Cho Khaing year2019 A. High specific speeds high flows and low heads I.

Centrifugal blower has three important parts namely fan volute casing and inlet duct. A method is presented for redesigning a centrifugal impeller and its inlet duct. The principles involved in the design of a blower is similar to that of acentrifugal pump except for the fact that the term centrifugal pump is.

Fluid model of centrifugal blower Osborne design methodology II. For many applications centrifugal blowers are preferred over axial as a method of rapidly and efficiently moving air. Centrifugal Blower design Premium components for efficient performance All blowers and compressors are custom-designed by us.

There are different methodologies used to design the impeller and other components of blowers. Design of 5 kW Radial Type Centrifugal Blower Casing Aye Mya Thandar1 Phyoe Min Than2 Nang Sein Mya3 Cho Cho Khaing4. A CAD model of centrifugal blower.

Although centrifugal blowers are developed as highly efficient machines design is still based on various empirical and semi empirical rules proposed by fan designers. The rotating impeller is attached to the fan wheel that catches the air flow and pushes it out the outlet. For example chemical processing corrosive gas handling dust collection dryers fume control process cooling and process heating.

Centrifugal Blowers also known as Centrifugal Fans use kinetic energy produced by the impellers of the Centrifugal Blower Fan to increase the pressure of the air stream which in turn moves them against the resistance caused by ducts dampers and other components. The air flow moves along the centrifugal direction or radial direction. Fluid model of centrifugal blower church design methodology 1 Fig.

ARID ZONE JOURNAL OF ENGINEERING TECHNOLOGY AND ENVIRONMENT. An impeller is a rotating component of a centrifugal pump that accelerates fluid outward from the center of rotation thus transferring energy from the motor that drives the pump to the fluid being pumped. These fans have the ability to rotate the air flow by up to 90 degrees.

Given the high performance of the baseline impeller the. 1 a conventional centrifugal blower includes an impeller 2having a plurality of blades arranged in a circular shape and a scroll casing 4formed outside of. DESIGN AND DEVELOPMENT OF A BLOWER FOR DOWNDRAFT BIOMASS GASIFIER.

DESIGN AND ANALYSIS OF CENTRIFUGAL BLOWER IMPELLER USING STEELS AND ALUMINIUM ALLOY Bharath Parshi1 AnoopKumar2 12Dept of Mechanical Engineering St. Step by Step designing the Spiral Casing of a Centrifugal PumpA pump casing is often referred to as a volute. DESIGN PROCEDURE OF RADIAL TYPE CENTRIFUGAL BLOWER IMPELLER 2 Design Specification of Radial Type Centrifugal Blower This research work is based on an industrial requirement for Twin city Blower Company Aerovent.

Below are some of the most common with links to more information and related fan designs. Radial blades have lower unit blade stress for a given diameter and rotationalspeed hence lighter in weight. Centrifugal fans utilize centrifugal force thus their name to increase the velocity of the airgas it passes between the fan wheel blades and exits at the tip of the fan wheel.

This pipe line connection is used to transport the waste from the machine to centralized blower. Industrial centrifugal fans and blowers accommodate a variety of applications. Indexed Terms- Centrifugal blowers fans Design Volute power Tabular Integration.

Large Centrifugal Fan Casing The Height Is About 4 Meters Contact Xianrun Blower Www Lxrfan Com Xrblower Com Xr Suction Fan Centrifugal Fan Industrial Fan

Centrifugal Pump Working Centrifugal Pump Mechanical Engineering Design Mechanical Design

Reverse Air Ventilation Fan Air Fans Centrifugal Fan Air Ventilation Fan Ventilation Fan Air Fan

Centrifugal Fan Maintenance Casing And Inlet Box Maintenance Centrifugal Fan Suction Fan Exhaust Fan

Air Flow Of Centrifugal Blower Vs Axial Blower Vankool Top Portable Evaporative Cooler Manufacturer In China Axial Evaporative Cooler Dyson Air Purifier

Backward Curved Impeller For Blowers And Fans Centrifugal Fan Exhaust Fan Industrial Exhaust Fans

The Working Principle Of Centrifugal Fan Centrifugal Fan Suction Fan Industrial Fan

Axial And Centrifugal Fans Centrifugal Fan Fan Mechanical Design

0 comments

Post a Comment